Reducing NOx emissions through Advanced Selective Non-Catalytic Reduction

by Aalborg Energie Technik a/s on Feb 15, 2023 4:20:46 PM

Boiler plant operators have many options when it comes to minimising their hazardous NOx emissions. Primary techniques can be used to prevent or minimise the formation of NOx, while a number of secondary techniques can be employed to reduce the NOx that has already been created.

Secondary reduction methods include Standard or Advanced Selective Non-Catalytic Reduction (SNCR), and Selective Catalytic Reduction (SCR). Some boiler operators also use a hybrid of SNCR and SCR.

Common to all of these methods is the use of a reducing agent like ammonia or urea, and each method has its own advantages and disadvantages. In this article, we look at the plusses and minuses of Advanced SNCR.

Advanced Selective Non-Catalytic Reduction

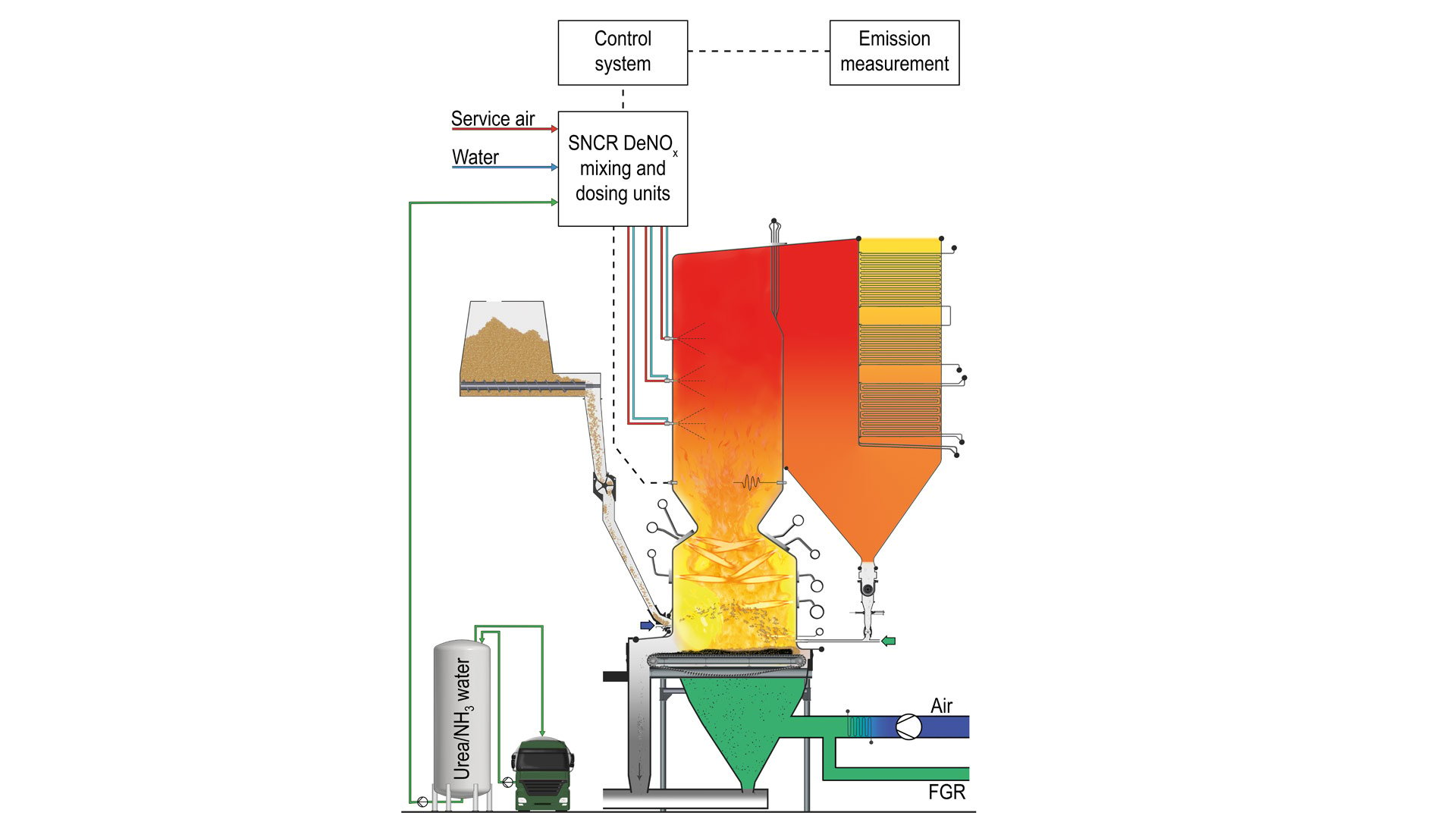

Advanced SNCR involves the reduction of NOx to nitrogen through a reaction with ammonia or urea. Advanced SNCR has more injection lances than Standard SNCR, as well as an online flue gas temperature measurement in the furnace. For optimal reaction, this occurs between 850 and 1090°C.

The Advanced SNCR solution is made with several injection levels in the furnace, which can be controlled independently of each other.

To support the reducing agent injection amount in each lance, an acoustic gas temperature measuring system (AGAM) provides 2D measurements of high-combustion gas temperatures.

The SNCR control system is interlinked with the boiler control system and set points are made in order to minimise the amount of reducing agent required and regulate NOx emissions and NH3 slip. The system is further optimised via online NOx, CO and NH3 slip measurements in the stack.

When introducing ammonia or urea, it is critical to consider reaction times. Ammonia water generally has a short reaction time, whereas urea takes longer to react. It is also important to ensure the right temperature. If the NOx reducing agent is injected at too low a temperature, the NOx will not react with ammonia, and high NH3 emissions will occur in the flue gas. If the NOx reducing agent is injected at too high a temperature, the ammonia will react with O2 rather than NOx, and the resulting NOx reductions will be minimal.

A potential by-product in the flue gas can be unreacted ammonia, called ammonia slip. Methods to minimise ammonia (NH3) slips in an Advanced AET SNCR system can be many, e.g.:

- Optimise or upgrade the primary NOx reduction methods.

- Reposition some of the lances or all lances to a higher furnace temperature.

- Some of the lances which are in a colder furnace temperature can be angled towards a higher furnace temperature (might require new injection lances).

- Add an extra level of lances for injection of ammonia or urea.

- There might be a difference in NOx formation across the furnace area, so the amount of injected ammonia might need to be individually adjusted to each lance, across the furnace area.

- Change of the NOx reducing agent.

- Use of ammonia NH3 slip catalyst.

- Contact AET Aftermarket, Nicolai Møller at nim@aet.dk or +45 3093 3289.

Advantages of Advanced SNCR:

- Typical NOx reduction of 50 to 85%

- Easy and simple integration

- High reliability

- Low maintenance costs

- Compact solution

- Low CAPEX compared to SCR.

Disadvantages of Advanced SNCR:

- Requires space for storage tank of reducing agent

- Slight impact on the boiler efficiency

- High water consumption, if poor atomising of reducing agent

- Higher consumption of reducing agent than SCR

- Higher reduction ratios may lead to higher NH3 slip.

Before deciding whether Advanced SNCR is the right strategy for your operation, be sure to read about the pros and cons of the other secondary techniques: Standard SNCR, Selective Catalytic Reduction (SCR) and a hybrid approach. You may also want to explore the various ways of stopping or reducing the formation of NOx in our article on primary techniques.

To learn more, download our e-book for an overview of the different NOx reduction methods and their potential, as well as NOx-related legislation.

Do you need help with your project?

Our experts are ready to assist you. Fill out the form below and we will get back to you as soon as possible.

Contact us

David Kjølby Krøger