How Selective Catalytic Reduction can reduce NOx emissions

by Aalborg Energie Technik a/s on Feb 15, 2023 4:35:56 PM

There are several ways that boiler operators can reduce NOx emissions from their operations. A number of primary techniques can be used to prevent or minimise the formation of NOx, while various secondary techniques can reduce the NOx that has already been created.

Secondary reduction methods include Standard or Advanced Selective Non-Catalytic Reduction (SNCR), and Selective Catalytic Reduction (SCR). Some boiler operators also use a hybrid of SNCR and SCR.

All of these methods involve the introduction of a reducing agent like ammonia or urea. The various methods of secondary reduction techniques each have their own advantages and disadvantages. This article takes a closer look at SCR.

Achieving NOx Reductions with Selective Catalytic Reduction in boiler systems

Selective Catalytic Reduction (SCR) is an effective technique employed to diminish NOx emissions originating from various types of boiler systems. By implementing SCR, significant reductions of up to 95% in NOx content within the flue gas stream can be achieved. The primary element of this system is the catalyst, which plays a pivotal role in the selective catalytic reduction process.

How does Selective Catalytic Reduction work?

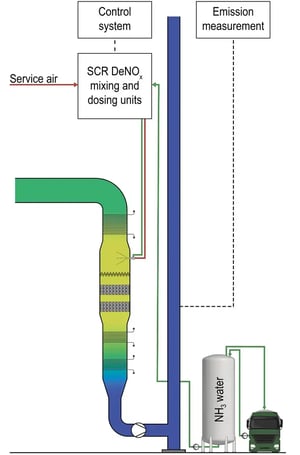

Selective Catalytic Reduction (SCR) works by injecting ammonia water into the flue gas. The evaporated ammonia water will then pass the catalyst elements, whereby NOx in the flue gas is transformed into nitrogen and water.

The operating temperature for the catalyst will typically be 190 – 260°C; depending on the levels of sulphur dioxide (SO2) and dust, and the regeneration sequence of the catalysts. In recent years, very low-temperature catalysts have become available that can operate at flue gas temperatures as low as 150°C.

Depending on the operating temperature of the bag filter, possible integration at existing sites and minimising the sizing of catalysts, reheating of the flue gas downstream of the bag filter might be required.

The DeNOx reaction takes place at the catalyst surface, reducing the flue gas NOx content to nitrogen and water vapour, at close to stoichiometric reaction with the injected NH3 water.

Since the catalyst is deactivated by alkali (Na, K), phosphor (P), and other ash-bound poisons, the preferred catalyst configuration for biomass combustion is in a low dust position downstream from the bag filter.

The catalyst surface might also be plugged by ammonium bisulphate if the flue gas temperature and flue gas SO2 content are not aligned.

Typically after three to five years of operation, the catalyst elements’ efficiency will drop. The catalyst elements, therefore, need to be periodically extended by an additional layer, cleaned, regenerated, or replaced.

A potential by-product in the flue gas can be unreacted ammonia, called ammonia slip. Methods to minimise ammonia (NH3) slips in an AET SCR system can be many, e.g.:

- Optimise or upgrade the primary NOx reduction methods

- Adding more catalytic volume (if you have a certain cross section, add an extra catalyst layer)

- Change to a catalyst with more active material inside

- Improve the distribution of ammonia water before the catalyst

- Use of hybrid SNCR and SCR

- Contact AET Aftermarket, Nicolai Møller at nim@aet.dk or +45 3093 3289.

Advantages of SCR:

- Typical NOx reduction of 50 to 98%

- Not sensitive to combustion variations

- Can adapt to variations in flue gas conditions

- Lower operational costs than SNCR

- Very low NH3 slip possible (< 2 mg/Nm3).

Disadvantages of SCR:

- Higher investment than SNCR

- Requires more space than SNCR

- Requires periodic replacement or regeneration of catalyst elements

- Sensitive to alkali metals

- Impact on heat balance.

Remember, Selective Catalytic Reduction is just one of several secondary techniques that can reduce NOx emissions. Be sure to read about the pros and cons of Standard and Advanced SNCR, and a hybrid approach that utilises both SCR and SNCR before deciding what is right for you. You can also learn much more about NOx reduction in our comprehensive e-book and via our Knowledge Hub.

Do you need help with your project?

Our experts are ready to assist you. Fill out the form below and we will get back to you as soon as possible.

Contact us

David Kjølby Krøger