How to source biomass and residues in an environmentally-friendly way

by Aalborg Energie Technik a/s on Dec 18, 2022 9:24:07 AM

If you are a chemical company that wants to move away from fossil fuels to decarbonise your operations, where should you source your biomass and residue fuels to power your chemical plant?

When designing and investing in a biomass and residue-fired plant, the question of where to source biomass and residue fuels from is important. The choice of fuel can impact the overall cost, particularly if sourced from afar. It also, obviously, impacts how environmentally-sound the fuel selection is.

How to approach locally-sourced biomass and residuals

Chemical plants typically want to identify the kinds of biomass and residues that are locally available to them and how to utilise them.

A case in point: Biomass Energy Solutions Vielle Saint Giron

This was the case for Biomass Energy Solutions Vielle Saint Giron, a cogeneration plant near Dax, France.

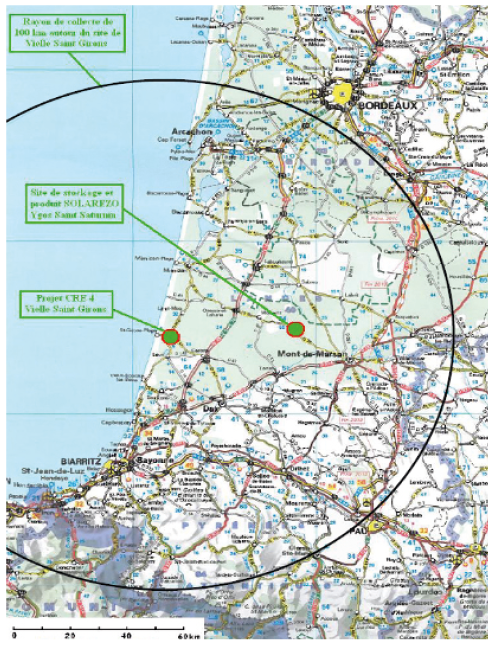

The plant owners wanted to minimise the environmental impact of transport, so they determined to source their biomass and residues from within a 100 km diameter circle surrounding their plant.

The plant only sources its fuels from within this circle, although the diameter may be increased if the biomass and residues are transported by rail or boat.

To minimise a potential lack of fuel by sourcing only local fuels, we recommend that chemical plants establish relationships with several suppliers within their local areas, although it is normally easier to deal with only one main supplier in daily operations.

We also suggest that plants consider alternative fuels such as trimmings and residues from agriculture. These can often prove to be a cost-free (or nearly cost-free) option with value, even if some regard them as low-grade residues.

Sourcing biomass and residues from landfill materials

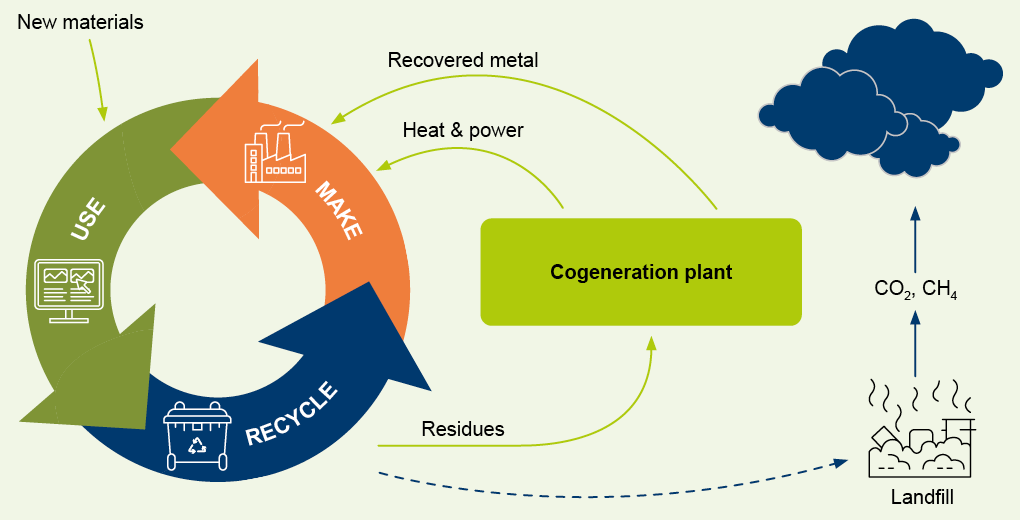

When considering the sources of your biomass and residual fuels, it is important to note that you can look to materials that otherwise would end up in landfills.

In fact, most of the biomass and residues being burnt for energy generation cannot be used any further in the circular economy and are therefore at their “End of Life”.

These “End of Lifers” are an ideal source of biomass and residues. Firstly, their use does not involve cutting down valuable trees. Secondly, if not used for biomass and residue fuels, it is highly likely they would end up as landfill or compost in which their slow degradation would release large amounts of CO2 and CH4 directly into the atmosphere.

Importantly, these landfill materials can be found locally, which means they will have not travelled thousands of kilometres and caused the type of harm to the environment that long-distance transportation usually entails.

In addition, the use of locally-sourced residuals help boost local economies, creating many jobs around their harvest, collection, transport and energy production.

To find out more about which biomass and residues should power your chemical plant, download our free e-book.

Do you need help with your project?

Our experts are ready to assist you. Fill out the form below and we will get back to you as soon as possible.

Contact us

David Kjølby Krøger