How to reduce your operational costs and decarbonise at the same time

by Aalborg Energie Technik a/s on Dec 18, 2022 9:27:14 AM

Our world faces serious challenges: climate change, limited resources and geopolitical instability are increasingly impacting our lives and are only likely to get worse in the future. Adding to that, there is now also an energy crisis in Europe with high energy prices as a result.

In addition to the environmental case for your chemical company to decarbonise, there are two further reasons why you should move away from fossil fuels: the current global energy crisis (e.g. lack of natural gas) and volatile fuel prices.

With the energy crisis and the increasing prices of fossil fuels, there is now an important economic incentive to decarbonise by transitioning towards biomass and residues.

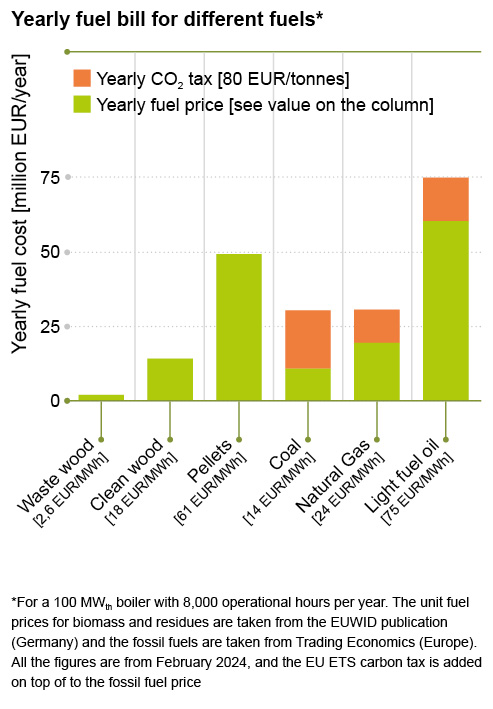

The graph below shows a selection of various biomass and residues as well as fossil fuels, their respective annual costs, including CO2 taxes in millions of euros for a 100 MWth boiler with 8,000 operational hours per year.

The overall picture is clear: using waste wood or wood residues instead of natural gas can save upwards of €30 million per year.

The overall picture is clear: using waste wood or wood residues instead of natural gas can save upwards of €30 million per year.

We know that increased CO2 emissions will not just cause climate change in some far-off future. We are already seeing some of the effects with severe heat waves, larger areas of droughts, rising sea levels and flooding of low-lying areas, intensified water cycles in the atmosphere and disrupted natural weather patterns.

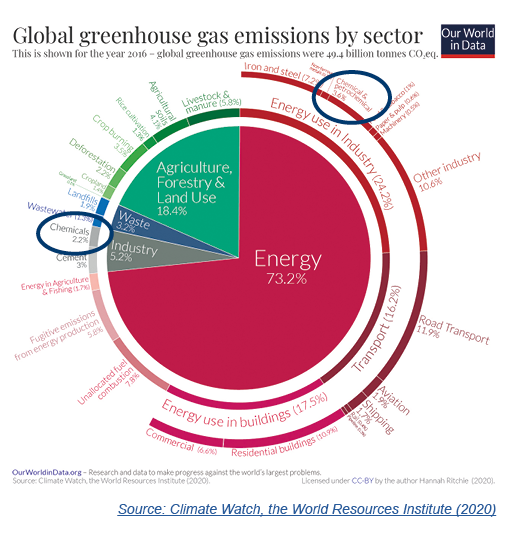

Unfortunately, the CHEMICAL & PETROCHEMICAL sector is one of the world’s largest CO2 emitters, accounting for 5.8% of greenhouse gases (GHGs), which is equal to app. 3 billion tonnes of CO2 per year.

Given the extensive heat and electricity required for chemical manufacturing, efforts to decarbonise will have a significant impact on the environment.

If the chemical sector moves its energy production away from fossil fuel combustion, it can make a big contribution towards the process of decarbonisation. By switching from fossil fuel to biomass and residues, chemical companies can make their energy production carbon neutral by 2050 and even carbon negative if they combine their efforts with effective CO2 capture.

All in all, a switch from fossil fuel to biomass and residues can deliver a highly efficient cogeneration plant producing the needed on-site steam, hot water and electricity. But most of all, it just makes good business and environmental sense.

To learn more about the business and environmental incentives to decarbonise, download our free e-book.

Do you need help with your project?

Our experts are ready to assist you. Fill out the form below and we will get back to you as soon as possible.

Contact us

David Kjølby Krøger